Over the last couple months, my A/C unit has cost me almost $1000. To be fair, I haven’t had to bite the bullet and drop $7000 on a whole new system, but that time is probably coming soon. I’m hoping to get through the killer summer months.

A couple months ago, I mentioned how I was going to clean the A/C unit while it was down. What happens is that the thermal switch in the compressor overheats and shuts the compressor down. This shutdown signal isn’t sent back to the thermostat, so the thermostat thinks things are still running just fine. The blower keeps blowing and the thermostat says the system is cooling and the fan is running. To reset this condition, I have to pull the thermostat off the wall and replace it, which then makes it read the current status of the compressor and starts everything back up again.

Well, after multiple resets, I had to call the repair company. I felt a bit foolish afterwards because the problem was just a bad cooling fan motor. Like, I’m so oblivious that I couldn’t troubleshoot that the cooling fan on the compressor wasn’t turning. That part was replaced for a little over $300 and I was back in business.

Last weekend, the house went up to 84 degrees again. I instructed the GF how to reset the thermostat until I got home. When I did get home, things were a little better but not much. That’s when I noticed the strange noise, like ocean waves. It was the blower in the attic ramping up and shutting off, over and over again. So this time, the compressor was running fine, the thermostat was saying everything was fine, but the blower was unable to supply enough cold air to the house to lower the temperature.

I put the house into emergency cooling mode. I closed all the blinds and pulled the curtains in all the rooms, closed the doors to all the rooms, closed off the vents and return in the game room, and turned on a window A/C unit on the lanai. I redirected the cool air into the house with a desk fan. You may think that’s funny, but the window A/C unit was able to keep the main part of my house (and sometimes the open master bedroom) at 78 degrees. And it did it for four days straight. That A/C unit hasn’t been run in years and stepped up to the task of cooling a whole house on a moment’s notice. Bravo, Kenmore.

I called the A/C tech in on Saturday and he identified that the blower motor needed changed, but he didn’t have one. It was a variable speed motor and they are specific to the exact make and model of A/C unit. They are also really expensive. So, repair was put off until Monday. On Monday, the repair company tried to contact the manufacturer for pricing and availability to no response. So at the end of the day it was decided to swap out the motor with a single-speed version. Monday night, I did a lot of research on variable speed motors and learned they have some significant benefits with regard to humidity control. But, since the whole system is in its final days, running a single-speed blower will do for now.

The tech came out Tuesday afternoon and quickly swapped out the motor. Looks like something I could have done myself, but, let the pros handle that mess. $600 for the motor and installation, and I was back in the cool life. The window A/C unit earned itself a nice long vacation, too.

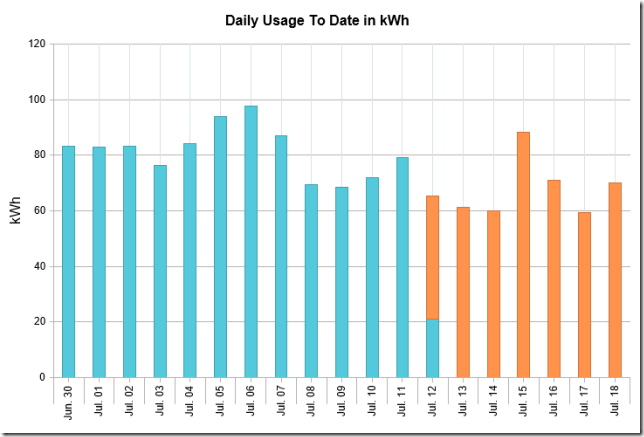

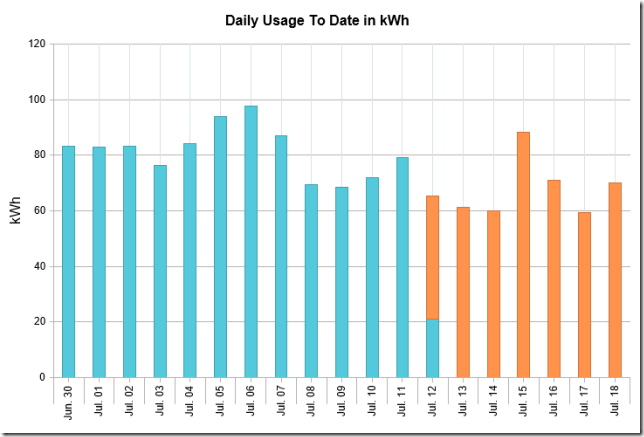

Referencing my electric company’s usage graph, you can kind of see what happened on Saturday the 15th. The A/C compressor was running non-stop because the thermostat said to. Midday on Sunday the 16th, I was worried about burning the compressor out, so I shut off the central air and just left the window A/C unit on. The 17th, the house was only cooled by the window A/C. Midday on the 18th, the central air was restored.