This weekend is an adventure in home maintenance. A little while ago I got to use a benefit of my "membership" in a HVAC maintenance program that costs me $20/mo. I don’t like having a subscription anything, but it’s whatever for now. One of the things I don’t like about it is you’re basically inviting them into your house so they can find stuff they want to sell you. And in return, you get the water in your hot water tank flushed. Oh boy. You know I’ve been doing that myself.

So anyway, on the first service, I got my tank flushed, and he went around looking for problems. First problem, all my emergency shutoff valves were frozen and needed replaced. Second problem, my lower thermostat on my hot water tank was blown. And the anode rod had never been changed in its 10+ years. So the hot water heater should be replaced. And all these problems are due to having hard water, so I should get a water softener. No big deal, they would write up quotes for all of this, and depending on how much I wanted done, it would only be between $1,000 (just changing the valves) and $7,000 (valves, hot water tank, and water softener).

Fuck. Off.

When it comes to work I feel capable of, I can bolt things off and on, but I don’t mess with fluids. Working on the car: power steering, brake, oil, etc. is a no-go. But this is just water, I think I can do it. I just need parts and some specialized tools

So I bought all the parts. Maybe $50 for all the valve kits, not $1000. I bought a couple tools that I ended up not using, too – you’ll see why. I also bought parts for the hot water tank. Maybe $100, not $2000. After a delay from freezing weather, I got to work.

I shut off the water to the house with a lot of difficulty and eventually bought a "curb key" that would make shutting off that valve easy. Should have bought it beforehand. With the water now off, I went inside and checked all the valves. Every one was able to be broken free. So no replacement needed, and no use for any of the parts and tools I bought.

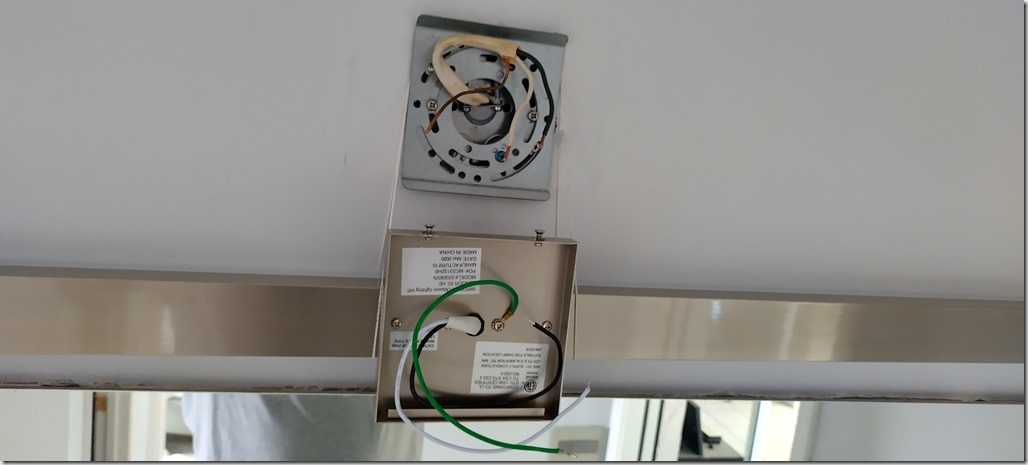

Then I went to work on the hot water tank. My impact wrench worked out well to remove the anode rod. And as far as the anode rod’s condition, when I finally got it out, I saw it was black, but it was only very mildly corroded. I swapped it out anyway since I had already bought the replacement. I actually had to saw the rod in half because it was so long I was stopped by the ceiling. Good thing I bought one of the multi-part replacement rods.

I had to run to Ace Hardware and buy a socket to remove the heater elements. While I was there, I also bought the curb key. The heater elements were pretty nasty. Replacing the thermostat and elements was easy, as long as I took my time and didn’t get overly frustrated.

I didn’t try and inspect the interior of the tank, but I’m going to assume it’s fine. No $2000 replacement needed, here.

But, while I had the hot water shut off and the cold water on at the water main, I found out I had cracked one of the valves while unfreezing it. I had a leak and my moisture alarm was screaming. Ok, so one replacement valve. And this led me to discover that the old valve handles are not compatible with the replacement parts. So back to Home Depot to get a new handle, while stopping at Lowes to return an unused tool.

After changing the one valve, I have not seen any leaks and the hot water is fucking HOT now, like scalding hot. I might actually turn it down a little. But anyway, SUCCESS!