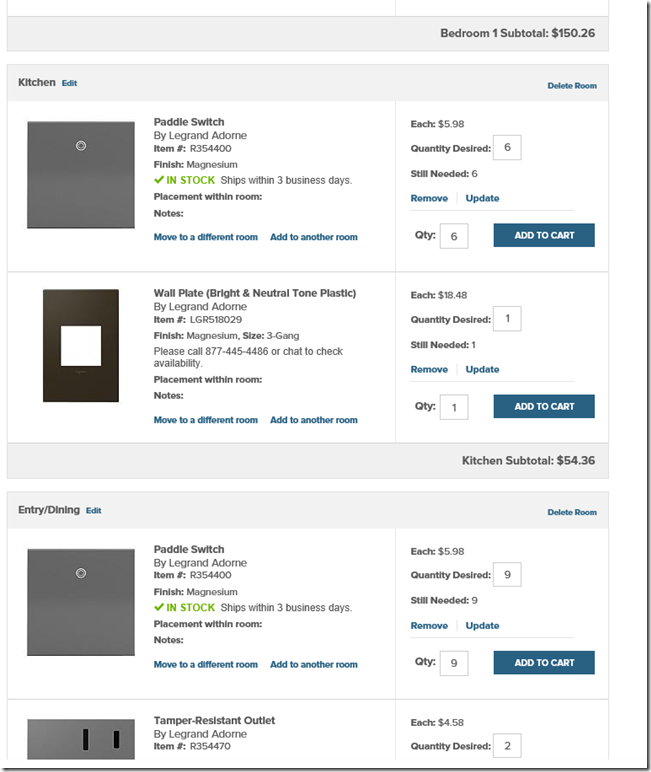

I talk a lot about consistency in the remodeling of the house. Right now, I have four different ceiling fans in all my rooms. I want to improve on that. Also, the master bedroom and living room have cheap contractor fans in white and shiny brass (although, matching!). Yuck. So I want to improve on those as well.

There are a lot of options out there for ceiling fans. It has been days upon days of searching for a style that I even liked. And, like my closet light, I found myself emotionally whipsawing between “That looks good” and “oh, it’s $600”. When you get used to going to a big box store and seeing things you want for $75-100, it skews your perception.

But I still had to find a style I liked. One of the bigger hurdles to overcome was that I didn’t want an integrated light, at least for these rooms. The bedroom fans will require one since that will be the only lights in the room. After a long time of searching, I did find a style I liked at a price I could live with.

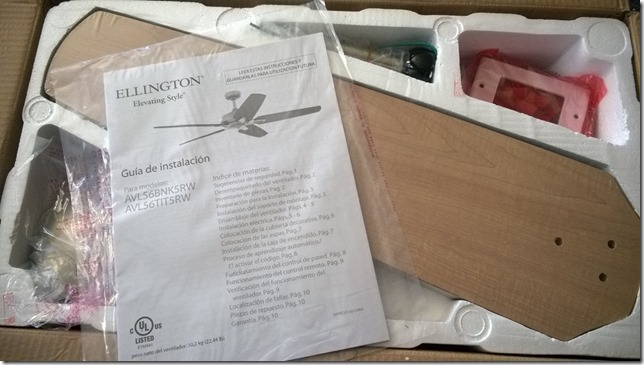

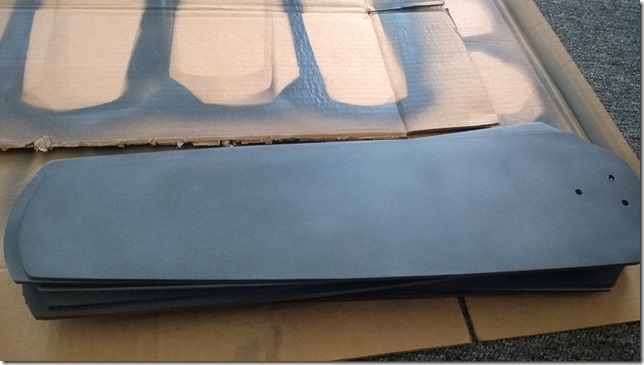

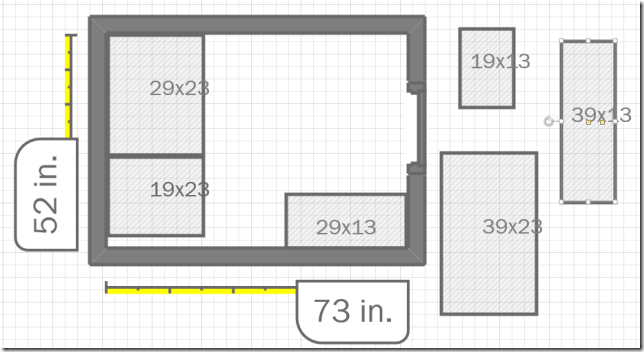

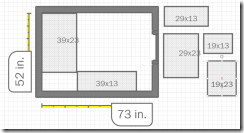

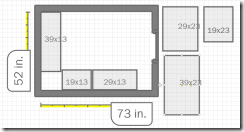

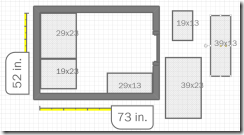

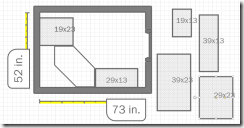

This fan is about $260, and I need two of them. I want the fans in the master bedroom and living room to match. Those are the two biggest rooms in the house, so the extra size (56” instead of the existing 52”) will be better suited. Then I started doing the research.

Both of the planned rooms have vaulted ceilings. When you have vaulted ceilings, you need to make sure the fan supports being mounted like that. I couldn’t find anything saying these fans could be. That means I couldn’t use these fans. But I didn’t want to believe that. I searched for angle mounting kits. I even visited a showroom and asked “experts”. They said that the fan could be mounted up to 20 degrees. I wanted to confirm this through another source, but I couldn’t find anything that said so. After a lot of hunting online, I finally ended up on the manufacturer’s website where I could download the installation manual for that fan model. Perfect. The manual showed that you could install the fan on a ceiling with a slope up to 25 degrees. My calculations say that my ceiling is 10-11 degrees, so that’s set. I dreaded having to find a different model of fan.

The next hurdle is the downrod. More of a concern than a hurdle, but the manual confirmed that the downrod could be swapped out with a longer one. The fan comes with a 6”, but I wanted 12”. Besides, the wider blades will probably require that extra space.

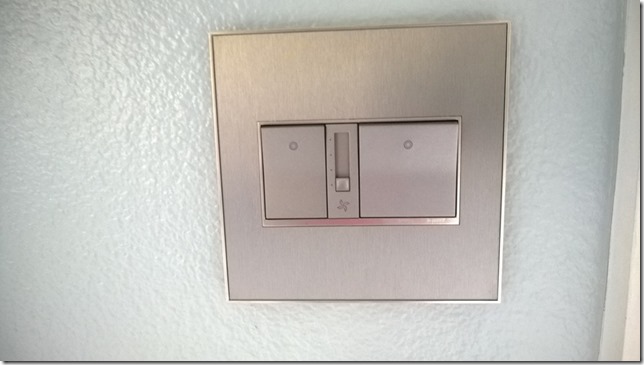

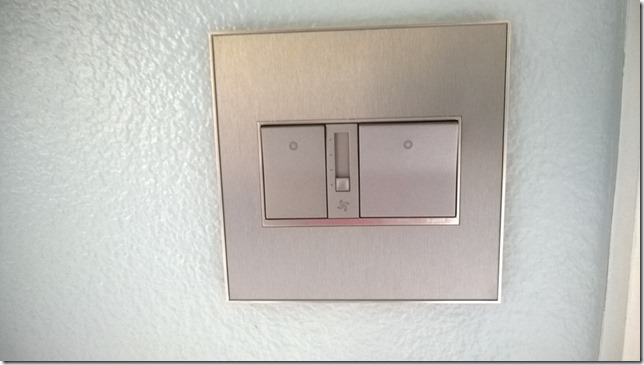

Then, as I read through the manual, I saw that the fan was run by remote control. Damn it. I looked closer and saw that you had to use their ugly remote control wall switch, too. That takes this fan out of the running, because I was set on using Adorne switches.

But I wouldn’t give up. I spent too much time getting this far to give up. I studied the manual and saw the fan itself had standardized wiring like any other fan. I saw the remote receiver was wired in-line with the fan’s wiring. What if I just eliminated the receiver? I searched for info on that idea and on a Home Depot forum, an expert confirmed that as long as the receiver isn’t integrated and it can be removed, you can use traditional wall controls with a fan that is remote-capable. Shortly after, I got an answer to an email I sent to the manufacturer that said I could hardwire the fan. This fan is a go. So the cost will be a little over $500 for two fans. Not bad considering a lot of fans I didn’t even like cost more than that individually.

Now, about that price. The particular model I wanted has been discontinued. Some online stores didn’t have them in stock anymore. The replacement model of the fan had a black body instead of titanium. I was willing to buy the current model until one of sites I visited (and I was on tons of websites) listed the discontinued model for $146 plus a 12% coupon. Well, that looks like a sign to jump on this offer.

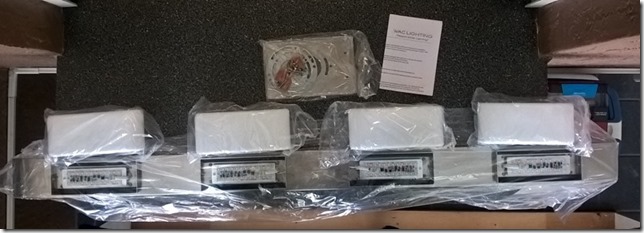

So, today I’ve ordered both fans plus two 12” downrods for a total of $267 – essentially half of my original budget. The downside is that it will take 4-6 weeks for delivery. That’s ok, I have plenty to do. Today, I also bought the Adorne switches and outlets for the master bedroom for $112.

Looking ahead, I need to find two matching fans for the bedrooms with integrated lighting. Then, one more fan for the lanai/office. I may repurpose a fan I’ve had in storage ever since I bought the house, as long as I can cap off the light fixture on it.