It’s been a really drawn-out project, this first major room I’ve been redoing. It started with the ceiling. It’s a big ceiling. Scraping off all the popcorn was a mess and a half. And then the sanding of the leftovers was even worse. I learned that I was using too fine of a sandpaper. I was using 120 grit and I should probably have used my 80 grit instead. So that took a lot longer than expected.

Then the patching. I think I did a pretty poor job of patching, but since the ceiling is so high, it’s not going to be as noticeable. Like previous attempts, I over patched, which required more sanding, then more patching, and on and on. Around most of the edges, I was down to the tape and oddly, in many places, there was a gap between the wall and the ceiling. I tried to fill those in with joint compound where I could.

Then the priming. I used up what primer I had left, which covered about a third of the ceiling. Then the next day, I went to Lowes to get more primer and was confused by what was there. The oil based, low-odor primer I was looking at had a green label. I was certain I had just finished a purple label can. The purple label was a water-based primer. Damn it. I’d been using the wrong primer this whole time.

So I got the oil-based stuff and worked with it that night. Let me tell you, there is a world of difference between the two. Oil based is smelly (despite being “low odor”), runny (like raining down on me and everything else), and it separates in the can into oil and solids (lots of stirring). But, the results of the oil based were significantly better, in my opinion. It really requires a different technique, though.

We’re many days into this project and I just barely have the ceiling started. I decide to prime the walls while waiting for some backup. The latex primer I bought went on ok, but thin. It muted the dark green well enough to paint over.

I finally get to the point of painting. I have the help of my awesome GF this time and while she cuts in on the ceiling, I roll. The results were decent. We decided we needed another coat up there, which we would do after knocking out the walls. The next morning, we tape up the ceiling and baseboards for protection and paint the walls. The accent wall is a deep, dark blue and it took about three heavy coats to cover it. The orange peel texture on the wall really worked against us there. the other walls were a medium grey and they also took multiple coats because of the texture. The results look great. The room is shaping up, finally!

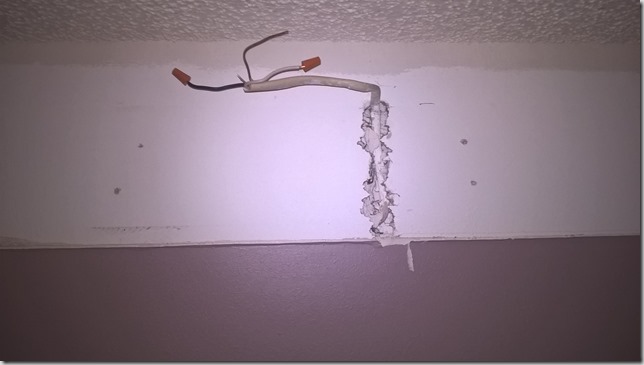

After drying, the GF does a quick test on the ceiling tape, resulting in disappointment. The painters tape is pulling off the ceiling paint. Oh well, it had to be retouched anyway. A couple of days later, I go to remove the rest of the ceiling tape. The tape is taking everything with it. It’s pulling off ceiling paint, ceiling spackle, and wall paint. It was leaving the ceiling in a total disaster.

To save the walls, I used an exacto knife to cut every tape seam in the room before pulling the tape off. Some places where I didn’t cut well enough pulled the paint off anyway. The ceiling now required a full repair, priming and painting. Over the next weekend, I patched it up as best I could (which is not expert grade), and primed it.

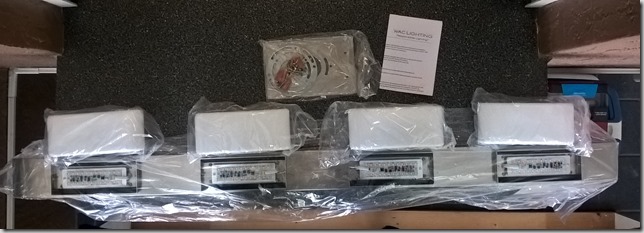

Last night, I repainted the ceiling again and am hoping to call it complete. I packed up everything in the room and swept the floor. In preparation, I brought the ceiling fan in and will finish up the outlets shortly. Then the bed and mattress get ordered and wardrobes purchased for the master closet. Then I can rest.